Is This Any Way to Run a City’s Schools?

Leaked CTU Proposals Won’t Do Anything to Improve Schools’ Poor Performance

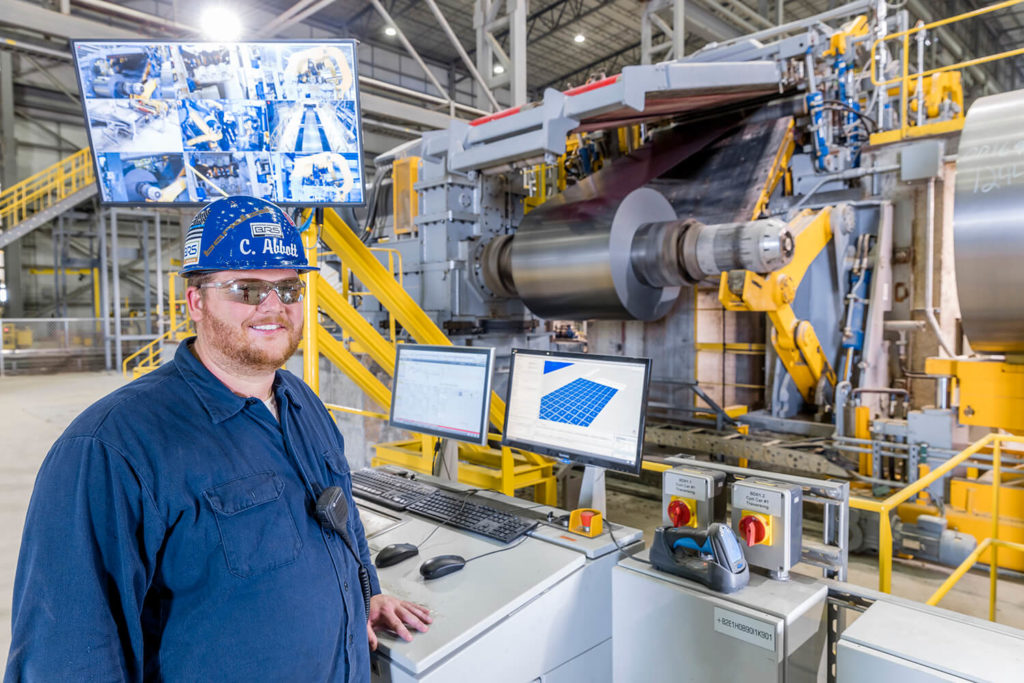

Right to Work State Hosts ‘Cleanest,’ ‘Fastest-Growing’ U.S. Mill

It was just five years ago this September that a brand-new company known as Big River Steel (BRS) broke ground on a $1.2 billion facility in a small town located in Right to Work Arkansas.

The BRS Flex MillTM in Osceola, Ark. (with an estimated population of roughly 7,000) has been in operation only since early 2017.

(As BRS has explained, a Flex MillTM is a “steel mini mill focused on the production of a wide product spectrum, including automotive steels and electrical steels.” The Osceola mill is the first such facility in the world.)

Just over two-and-a-half years later, it is “producing 4,500 tons of hot-rolled steel each day or about 1.65 million yearly,” according to a recent report for Forbes magazine by business journalist Jonathan Ponciano.

The headline for Mr. Ponciano’s article about BRS calls the company “America’s cleanest and fastest-growing steelmaker.”

By 2017, Right to Work States’ Share of U.S. Primary-Metals Output Had Risen to 62.1%

And the remarkable success of this young manufacturing business and its employees vividly illustrates how the future of U.S. metal production is located in states with Right to Work laws.

Data from the U.S. Commerce Department’s Bureau of Economic Analysis (BEA) website clearly show America’s new metal manufacturing industry is located in states that legally protect employees’ freedom to work without being forced to join or bankroll a union.

As recently as 2007, according to the BEA, just 32.5% of America’s $51.33 billion (in 2012 dollars) in primary-metals manufacturing emanated from the 22 states that then had Right to Work laws on the books.

By 2017, the most recent year for which state data are available, the entire U.S. primary-metals-manufacturing GDP had risen to $68.61 billion in constant 2012 dollars, a gain of nearly 34%.

And, within just a decade, Right to Work states’ share of all U.S. primary-metals output had risen to 62.1%!

National Right to Work Committee Vice President Matthew Leen explained:

“Right to Work states’ new dominance of metal-industry output is partly a consequence of the passage and implementation since early 2012 of new Right to Work laws in five states, including Indiana, the top producer in the country.

“But that’s far from the whole story. From 2007-2017, real primary-metals-manufacturing GDP in the 22 states that had Right to Work laws on the books for the whole decade soared by 35.6%.

“That aggregate percentage increase is nearly 80% greater than the overall gain for the 23 states that still lack Right to Work protections today.”

Highly Productive Workers Earned an Average of $129,000 In 2018, Including Bonus Pay

Mr. Leen added that the new facilities springing up in Right to Work states like Arkansas are extraordinarily efficient, and production employees’ pay reflects that fact.

According to Mr. Ponciano, the cash flow per union-free employee at BRS, the “most technologically advanced” steel producer in North America, is “a whopping $557,000.”

That’s roughly nine times as great as the $61,000 cash flow per union-impaired employee at troubled U.S. Steel.

And last year, Mr. Ponciano added, the average BRS production worker earned $129,000, including bonus pay, in a state where the cost of living is 12% below the national average, according to the nonpartisan Missouri Economic Research and Information Center.

Right to Work Laws Foster ‘An Ideal Environment For Modern Manufacturing’

In the words of New Yorker contributor Benjamin Wallace-Wells, who at a visit to Osceola last year witnessed “a young man in a new BMW 3 Series” whizzing by on his way to his shift, BRS jobs pay “impossibly well.”

“The manufacturing jobs of the 21st Century require employees who are willing and able to develop their skills and show individual initiative,” noted Mr. Leen.

“Right to Work laws foster an ideal environment for modern manufacturing by empowering the individual employee.

“First and foremost, they empower employees who disagree with Big Labor obstruction and ‘hate the boss’ class warfare to resist by quitting the union and withholding all financial support for it.

“That’s a key reason why the 27 Right to Work states are attracting a wide array of high-paying manufacturing jobs and businesses.”

Leaked CTU Proposals Won’t Do Anything to Improve Schools’ Poor Performance

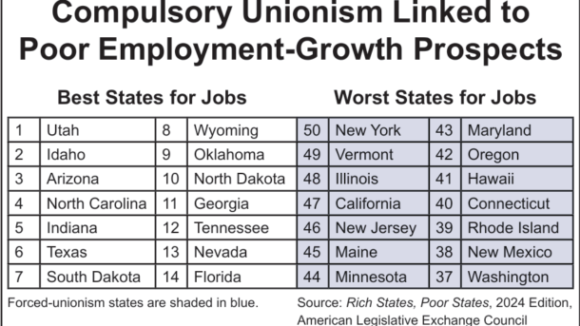

Wherever Big Labor wields the power to collect forced union dues, union bosses funnel a large share of the confiscated money into efforts to elect and reelect business-bashing politicians. Employment growth tends to lag as a consequence.

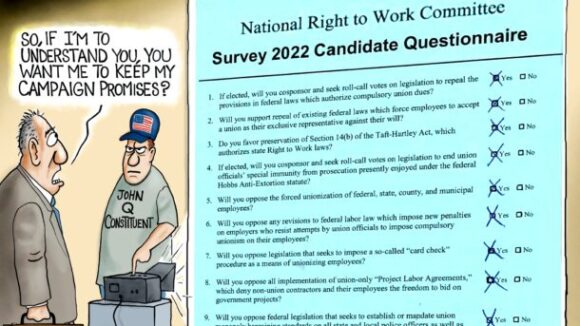

Members Insist They Keep Pro-Right to Work Campaign Promises